Blog

Design Considerations Before Embarking on Electronic Circuit Board Assembly

July 16, 2018

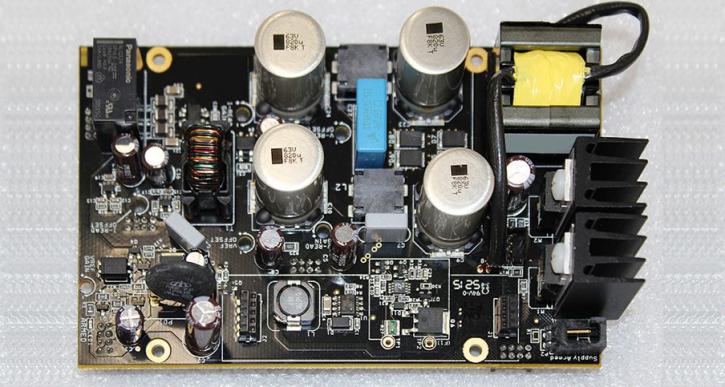

It may seem counterintuitive to think, but electronic circuit board assembly actually begins long before the gears start turning on the production line. From laying out traces, choosing thickness and the substrate material, simulating component placement and more, this earliest stage of electronic circuit board assembly is perhaps the most crucial of all.

Electronic circuit board assembly begins not when the production line starts running but at the design stage itself because that’s what will determine the performance of the board and manufacturing complexity.

In this article we look at some very important decisions that must be taken in relation to electronic circuit board assembly.

- Placement – In an ideal word you would have the most compact board which could fit all of your components. However, given the limitations with the depth of the board and the circuit traces, material strength and heat dissipation, component placement can be quite subjective. The orientation of the components, the complexity in placing and soldering them will determine not only the performance of the board but also the speed and cost of electronic circuit board assembly.

- Signal traces – A temptation for designers, which they must endeavour to abstain from indulging, is making signal traces thin and complex. See how a trace branches out repeatedly, and watch that signal quality drop. Also, pushing electronic circuit board assembly to the limits of width and gap is a recipe of arcing. A designer should consider ‘will the board perform as I intend it to in conditions that are less than ideal’.

- Heating – Heat is something that is not easily visualized at the pre- electronic circuit board assembly stage. It takes expertise to recognize where heat build-up might be an issue. Components that may be operating just within their heat limits can easily surprise designers when they begin to overheat once the board is placed in a more realistic setting.

- Verify design – Checking the final design once, twice, thrice over is less time consuming and certainly a lot cheaper than, say, finalizing a board for electronic circuit board assembly which has obvious deficiencies.

No comments yet...

Post a Comment

*** Your email address will not be published.