Blog

Similar to other manufacturing processes, there are many factors during PCB assembly that can affect the reliability and functionality of the printed circuit board. These factors include material and design of the stencil being used, the solder paste, the placement of the varying components, and more. It is also important to take into consideration the actual PCB and SMT equipment used, as well as the specific requirements needed.

For quality assured and reliable PCB assembly, look no further than Permatech Electronics!

Solder Stencil and Soldering

In general, stencil thickness is typically matched to the needs of all the components in a printed circuit board. The solder paste can be applied onto the board through screen printing, while the volume is dictated by stencil thickness and aperture. If the stencil thickness does not meet all the components on the same board, a step-down stencil will be considered.

During PCB assembly, electroformed stencils, made from nickel or stainless steel, are used to ensure a uniform and quality soldering to the board. Additionally, it is advised to go around the corners of the apertures to provide good paste release. The apertures for the solder joints must have the same size to the metal pads placed on the board. Lastly, in order to achieve the best results during assembly, the stencil should be segmented into smaller and multiple openings.

Component Placement

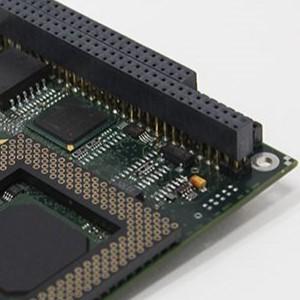

Modern automatic component placement equipment utilizes vision systems in order to attain accurate and reliable printed circuit boards. In this technique, both the board and the components are measured through optical means. Then those individual components are properly mounted at their respective spots, which are programmed on the board. Prior to placing the components, they are detected by a vision system which recognizes the packages and enables them to be placed correctly. Other placement systems can be used as long as the desired component placement is obtained.

At Permatech Electronics, we promise to deliver functional and reliable printed circuit boards to all of our valued clients. Our team has been in the business of manufacturing and distributing circuit boards since 1992. Call or email us today to learn more about our products and services.